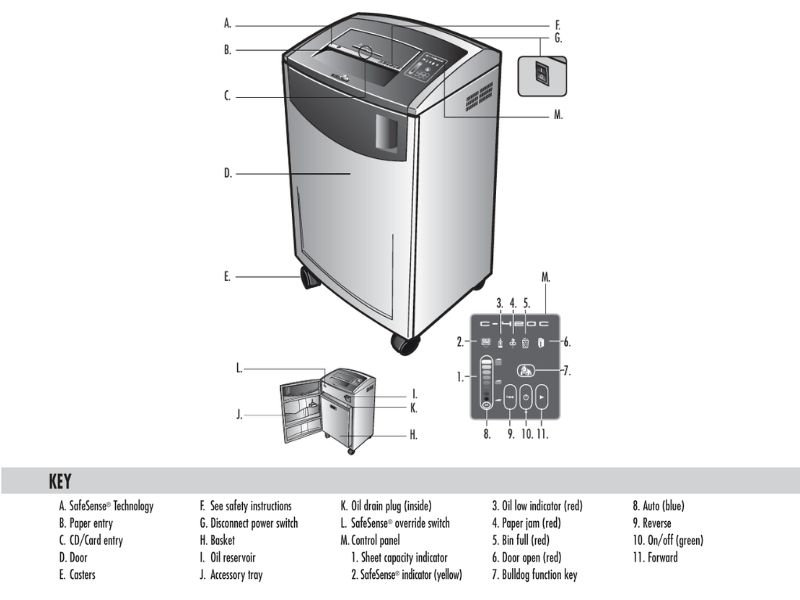

The Fellowes C-420C shredder is a trusted office companion, equipped with advanced sensor technology for automatic paper detection and safety features. However, sensor issues, such as misreads, blockages, or sensitivity problems, can disrupt its operation, causing frustration.

This guide dives into common sensor-related problems and provides practical solutions to clean, reset, and maintain sensors, ensuring optimal performance and extended lifespan.

Why Addressing Sensor Issues Is Important

Sensors play a vital role in the seamless operation of your shredder by automating functions like start, stop, and reverse modes.

Here’s why addressing sensor issues promptly is crucial:

- Ensures Smooth Shredding: Misaligned or blocked sensors can prevent the shredder from operating, leading to downtime.

- Improves Longevity: Regular sensor maintenance reduces wear on the motor and prevents unnecessary strain.

- Maintains Safety: Features like SafeSense® rely on accurate sensor detection to protect users from accidental harm.

Common Fellowes C-420C Shredder Sensor-Related Issues & Troubleshooting

The sensors in the Fellowes C-420C shredder play a critical role in ensuring smooth, automated operation. When these sensors malfunction, it can disrupt shredding, trigger false activations, or halt operations entirely.

Below are common issues users face and how to resolve them effectively.

1. Sensor Misreads or False Activations

The shredder may stop working without cause, refuse to detect paper, or activate when there’s no input.

Causes:

- Dust particles blocking the infrared sensors.

- Misaligned or faulty sensors.

Solutions:

- Perform a Visual Check: Look into the paper feed area for obvious obstructions, such as dust or leftover paper fragments.

- Reset the Shredder: Unplug the device for 5 minutes, then plug it back in. Sometimes, a simple reset can recalibrate the sensors.

- Advanced Cleaning: If basic cleaning doesn’t work, clean the sensors using compressed air followed by a gentle wipe with rubbing alcohol.

2. Sensors Blocked by Debris

The shredder fails to start even when paper is inserted, or stops mid-operation.

Causes:

Paper fragments lodged in or around the sensor area.

Solutions:

- Remove Visible Blockages: Use tweezers to extract stuck pieces. Be careful not to scratch the sensor surface.

- Prevent Future Blockages: Always shred clean, dry paper and avoid feeding materials like labels or paper with adhesive.

3. Overly Sensitive Sensors

Sensors falsely detect hands or objects, stopping the shredder unnecessarily.

Causes:

Ambient light interference or nearby reflective surfaces.

Solutions:

- Adjust Placement: Position the shredder in a location away from windows or bright lights. Avoid placing it near mirrors or glossy objects.

- Calibrate SafeSense®: Recalibrate the sensitivity by toggling the override buttons, as instructed in the manual.

Step-by-Step Guide to Cleaning and Resetting Sensors

Cleaning and resetting the sensors of your Fellowes C-420C shredder ensures they operate correctly and detect paper accurately. Here’s an in-depth, step-by-step process:

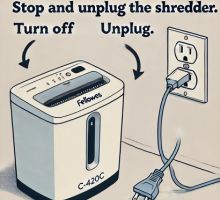

Step 1: Power Down the Shredder

- Why: Unplugging the shredder eliminates any risk of accidental activation during cleaning or maintenance.

- How: Turn off the shredder and unplug it from the electrical outlet. Wait for a few minutes to ensure the components cool down.

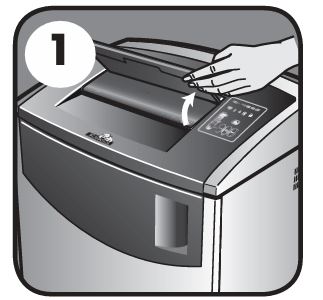

Step 2: Access the Sensor Area

- Why: Sensors are typically located near the paper feed slot. Proper access ensures thorough cleaning.

- How: Open the paper entry slot and inspect the area for visible sensors. Refer to your manual for the exact location.

Step 3: Perform Initial Cleaning

- Why: Surface debris like dust and paper fibers often cause misreads.

- How:

- Use a can of compressed air to blow away loose dust.

- Gently wipe the sensors using a cotton swab dipped in rubbing alcohol. Avoid using excessive moisture, as this can damage sensitive components.

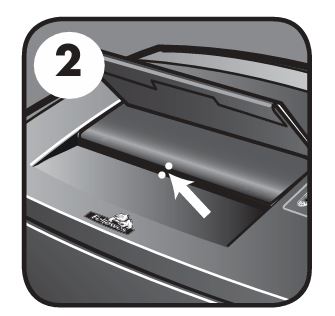

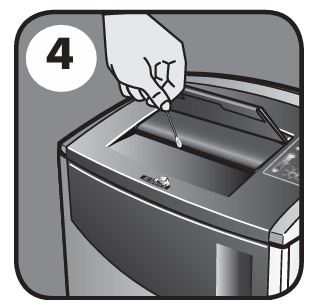

Step 4: Inspect for Embedded Debris

- Why: Paper fragments can lodge near the sensors, obstructing proper function.

- How:

- Use a flashlight to spot tiny debris around the sensor area.

- Carefully remove these fragments with tweezers or a soft brush.

Step 5: Test Sensor Alignment

- Why: Misaligned sensors may fail to detect paper or trigger false activations.

- How:

- Check the positioning of the sensors to ensure they’re parallel to the paper feed.

- If necessary, adjust their alignment gently using a non-metallic tool.

Step 6: Reset the Sensors

- Why: Resetting clears previous sensor memory and recalibrates them for normal operation.

- How:

- Press and hold the reset or power buttons (consult your manual for the exact reset procedure).

- Wait for the indicator lights to reset before testing the shredder.

Step 7: Test the Shredder

- Why: Verifying proper function ensures the issue has been resolved.

- How:

- Plug the shredder back in and power it on.

- Insert a single sheet of paper to test sensor responsiveness. If the shredder operates smoothly, proceed with regular usage.

Preventive Maintenance Tips for Shredder Sensors

Maintaining the sensors in your Fellowes C-420C shredder is essential for avoiding operational hiccups and ensuring its longevity. These preventive tips will help keep your shredder sensors in optimal condition:

1. Clean Sensors Regularly

- Dust and paper debris can accumulate on sensors, leading to misreads or failure to detect paper.

- Use a soft cotton swab dipped in rubbing alcohol to gently clean the sensors every two to three weeks, or more frequently in dusty environments. Avoid using harsh cleaning agents or excessive moisture.

2. Avoid Feeding Sticky or Dusty Materials

- Adhesive residues from labels or dust from shredded materials can clog sensors and create operational problems.

- Stick to shredding clean, dry paper. Avoid feeding adhesive materials, laminates, or papers coated with dust or residue.

3. Inspect for Blockages Periodically

- Paper fragments or debris lodged near sensors can cause them to malfunction.

- After heavy shredding sessions, inspect the paper feed and sensor area for blockages. Use tweezers or compressed air to remove any fragments.

4. Monitor the Working Environment

- External factors like light interference or dust in the surrounding area can impact sensor performance.

- Place the shredder in a clean, well-lit, and dust-free area. Avoid positioning it near windows, mirrors, or reflective surfaces that might interfere with the sensors.

5. Test Sensor Functionality Monthly

- Regular testing ensures the sensors remain responsive and calibrated.

- Insert a single sheet of paper into the feed slot. If the shredder starts automatically, the sensors are working correctly. If not, clean and recalibrate the sensors as needed.

6. Lubricate Blades Regularly

- Proper blade lubrication reduces strain on the motor, indirectly preventing sensor issues caused by motor-related interruptions.

- Use Fellowes-approved shredder oil to lubricate the blades every time you empty the waste bin or after every 500 sheets.

Frequently Asked Questions (FAQs)

How often should I clean the sensors on my Fellowes C-420C shredder?

It’s recommended to clean the sensors every two to three weeks or whenever you notice performance issues such as misreads or failure to detect paper.

Can I use any cleaning solution to clean the sensors?

No, only use a cotton swab dipped in rubbing alcohol or a similar non-abrasive cleaner. Avoid water or harsh chemicals that may damage the sensor components.

What should I do if the shredder stops mid-operation without a jam?

This could indicate a sensor misread. First, check and clean the sensors to ensure they are free of dust or debris. Then, reset the shredder to recalibrate the sensors.

Why does my shredder auto-start when there’s no paper inserted?

This may happen due to dust or fragments blocking the sensors, causing false activations. Clean the sensors and ensure there are no reflective surfaces nearby.

How can I prevent sticky residues from affecting sensor performance?

Avoid shredding adhesive materials like labels, sticky notes, or glue-bound paper. These can leave residues that block or confuse the sensors.

Can sensor misalignment cause shredding issues?

Yes, misaligned sensors may fail to detect paper or trigger false activations. Inspect and adjust the sensor positions carefully according to the manual instructions.

What if sensor issues persist after cleaning and resetting?

If problems continue despite maintenance, consult the Fellowes support team. Persistent issues may indicate a need for professional repair or sensor replacement.

Conclusion

Proper sensor maintenance is crucial for the smooth operation of your Fellowes C-420C shredder. By addressing common sensor-related issues like misreads, blockages, and sensitivity problems, you can prevent downtime and prolong your shredder’s lifespan.

Proper cleaning, careful alignment, and following the troubleshooting steps outlined here will ensure your shredder performs at its best, keeping your document disposal process hassle-free.